The quality of cryoglobulin analysis is dependent on the control of the sample centrifugation process. Until 2021, there was no reliable control of the different parameters affecting centrifugation and the only guarantee depended on good technical control by the laboratory. The clinical interest associated with the result of the search for a cryoglobulin, its determination and its characterization are no longer to be demonstrated. Therefore, finding ways to improve temperature control, crucial for the quality of this analysis, had become essential for many hospital laboratories who were calling for it.

After a reminder of the importance of the examination and temperature control in the pre-analytical phase, we will see how the APHP has taken control of this control for the centrifuges dedicated to cryoglobulins on its St Louis and Lariboisière sites.

What are cryoglobulins and why is the centrifugation temperature critical?

Cryoglobulins are multimolecular complexes that include at least one class of immunoglobulins, sometimes in combination with other proteins. They precipitate at low temperatures and are dissolved again when the serum is warmed to 37°C [1]. Cryoglobulins can be used to diagnose lymphoplasmacytic hemopathies, immunoproliferative diseases and chronic inflammatory autoimmune, infectious or viral diseases [2].

The respect of a temperature of 37°C is therefore critical in the context of cryoglobulins, as their determination and analysis present a high frequency of prescription, and until 2021, there was no possibility of temperature control for this examination at all stages of the process. The quality of the analysis depended on the good technical control of the laboratory.

Sample collection and transport, temperature maintenance at 37°C is crucial

Cryoglobulin can precipitate at different temperatures from one patient to another, and up to 36°C. This shows the extreme attention that must be paid to temperature from the pre-analytical phase of this examination.

Essential points of vigilance at the time of sampling:

The sample must be taken from a patient who has been fasting for 12 hours. The sampling room does not have to be heated to 37°C. Gel-free and additive-free tubes are preferred and should be heated to 37°C. Generally, 3 dry vacuum tubes of 5mL (or 2/3 tubes of 7mL) are recommended. The volume of serum will thus be 5 mL.

Transport of the sample: Control the temperature!

Blood sample transport must preserve a 37°C temperature . Device choice is therefore crucial.

Several solutions are used by biochemistry laboratories:

15 L Coleman-type thermostatic suitcase heated to 37-39°C

Insulating bags with thermal pads

Thermos of Fontainebleau sand placed in an oven at 37°C

An expert we know well here recommends :

A temperature-stable solution for transporting samples in a car shuttle: the microbiological incubator

A more economical solution of transport bag with 37°C accumulator

Two bags should be provided for a hospital of 1000 beds / 500 annual analysis cases, and they should be equipped with a traceability / location system.

Coagulation and centrifugation: Check the temperature!

When they arrive at the laboratory, tubes are placed in an oven at 37°C. In this oven, coagulation takes place for a minimum of 2 hours, 5 hours recommended, and never more than 24 hours to avoid hemolysis.

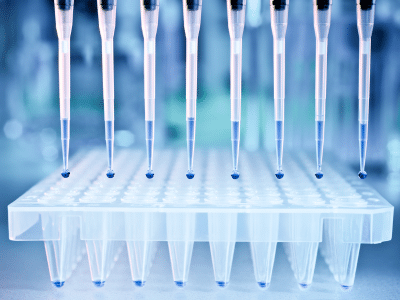

The recommendations for centrifugation are 3500 rpm (revolutions per minute) for a quarter of an hour, at 37°C in a thermostatically controlled centrifuge. The buckets can be preheated to 37°C.

It is the absolute respect of this temperature maintenance at 37°C of the sample at the end of the dynamic centrifugation phase, which guarantees the reliability of the results of the cryoglobulin tests.

Relying on a COFRAC-accredited method of temperature control in a moving centrifuge: the APHP experience

When Ms. Güler Aydin and Ms. Magali Thoraval, in charge of metrology at the Groupe Hospitalo-Universitaire AP-HP. Centre-Université de Paris (Cochin, Necker, Hôpital Pompidou, etc.) were audited by COFRAC during the audit of their processes, they were asked about the control of temperature in the dynamic phase of centrifuges. Thinking that there was no partner able to carry out this type of metrological control, they thought they would be exempt from any deviation noted by the auditor.

However, since September 2021, a metrologist in the laboratory has deployed a dedicated verification method, subject to COFRAC accreditation n° 1-2479 – scope available on www.cofrac.fr

Would you like to be supported by an innovative partner, whose metrological expertise is based on the needs of the laboratories it supports?

You can fill in this form, we will contact you!