Dangerous liquids is a critical issue in the laboratory, especially when it means a potential risk to the technician.

Choosing the right technical solution can be difficult.

Dangerous liquid: what about their risks?

There are significant risks when handling potentially toxic products. These risks include skin contact, eye contact or inhalation of vapors/aerosols. Risk training helps to reduce these exposures.

This means that technicians must have personal protection systems: goggles and gloves must be available to reduce the accident risk in the laboratory.

The laboratory configuration must be adapted to these risks in order to define appropriate ventilation systems, rooms, waste collection systems…

Choosing the right dangerous liquid dispenser completes the right risk management.

How equipment impacts security management?

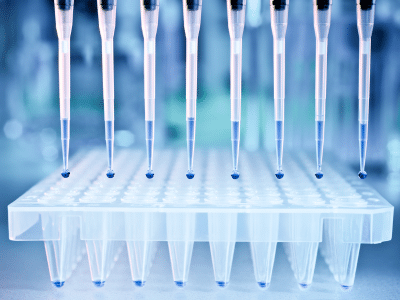

Dispensers are good equipment for collecting a precise liquid quantity from a bottle and dispensing it accurately.

With its bottle, the dispenser is considered a closed dispensing system. This means that it reduces evaporation and aerosols from toxic products.

The dispenser should be connected to the bottle with adapters if necessary.

For more safety, it is possible to add a valve before the outgoing liquid.

This accessory has 2 functions:

– During the system purging, there is no loss of liquid because it goes back into the bottle.

– Blocking of the distribution to avoid distributing liquid if it is not necessary.

High performance material for excellent chemical resistance

Dispensers are often chosen to handle very aggressive chemicals such as acids, bases or solvents.

Designing a dispenser with a high-performance material is the right way to ensure precise and accurate dispensing over a long period of time.

The constraints are multiple: mechanical, chemical and thermal. This is why manufacturers choose high quality materials such as PTFE, PVDF, glass, platinum… The glass parts are covered with a protection to avoid the dangerous liquide leakage in case of breakage or shock.

Chemical resistance chart is available to confirm your choice.

When durability and environment are linked to easy and simple maintenance

Liquid flows through many parts of the dispenser during handling.

All parts are in direct contact with the liquid.

Cleaning is therefore very important to avoid blockages caused by crystallizing solution, for example.

This cleaning is simplified since all parts are removable and can be changed!

This ensures a longer shelf life with respect to the environment.

Besides, the dispenser must resist to 121°C to allow an autoclave cycle for a perfect decontamination.

Safety is supplemented by performance

The dispensers are volumetric piston equipment and must comply with ISO8655.

The manufacturer must issue a certificate confirming that the equipment dispenses an accurate and precise volume.

As with all precision equipment, dispensers should be checked annually to ensure that there are no performance discrepancies.

Choosing a model with a calibration system is a good way to ensure accurate and precise volume for accurate analysis results.

Don’t forget ergonomics

Workstation ergonomics are important for personnel safety.

This is a central point for the micropipette but also for the dispensers:

- User-friendly for both aspiration and dispensing steps

- Simple volume adjustment

- Easy volume reading

- Ergonomic installation

In conclusion, technician safety is a priority when choosing a dispenser for aggressive liquid handling.

The choice of high-performance equipment, ergonomics, user-friendliness and user-friendly maintenance are the key points!

To know more about ergonomics in the laboratory, discover How to design a customized laboratory in every detail: benches, furniture and colors…