Metrological non-conformity: a critical challenge in the industry

Metrological non-conformity is a hot topic in the industrial sector, having a significant impact on the quality of products and industrial processes. In this article, we explore the potential consequences of metrological non-conformity and the innovative solutions LABELIANS proposes to deal with them.

Understanding Metrological Non-Conformity

Metrological non-conformity is declared when measurement results do not match the defined specifications. This term may sound technical, but it is essential to understand it to grasp the extent of its consequences.

Increased Risk of Accidents and Safety Issues

Instrumental drift can lead to accidents or safety problems. A metrological non-conformity may be detected during calibration of a sensor (e.g. temperature), but arrive too late. Advances such as metrology 4.0 (miniaturization and multiplication of sensors, quantitative and qualitative data collection) now make it possible to detect problems quickly, and to control, minimize and anticipate risks to workers and installations.

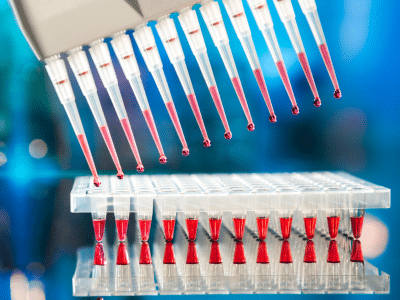

Lower Product Quality

A consequence of the drift of an industrial process detected during a metrological non-conformity can be a decrease in product quality over a given period of time. In the food industry, for example, this could mean distributing products that do not meet food safety standards for an indefinite period of time. Innovative solutions, such as the use of intelligent sensors and the constant collection and analysis of information using cutting-edge technologies, provide permanent control of the process and a guarantee of product conformity.

Higher Production Costs

Dealing with metrological non-conformities can lead to additional production costs due to production delays and product scrap. Innovations such as the automation of measurement processes, self-calibration of sensors, or the use of quality management software and high-performance tools can reduce these costs by minimizing non-conformities and optimizing processes.

Loss of Customer Trust

Metrological non-conformities can erode customers’ confidence, requiring them to take onerous remedial and corrective action. They can call into question the quality of the products and services supplied, and the control of their processes. International System traceability, certification and accreditation reinforce customer confidence by guaranteeing the quality, competence and reliability of results.

Innovative Solutions by LABELIANS

At LABELIANS, we are committed to providing innovative solutions to navigate the challenges of metrological non-conformity. With our expertise and cutting-edge solutions, we are your trusted partner for ensuring quality and safety in your industrial processes.

If you have any questions or need support, please contact customer service on 01 64 45 42 42 or by e-mail: serviceclient@labelians.fr