In the laboratory, many analyses require the use of test tubes. There are as many applications as there are fields of application, be it in biology, clinical, chemistry, centrifugation, storage or general laboratory use. How to select your ideal test tube? Here are 5 selection criteria to guide you.

5 main materials for the test tube body

To begin with, we can distinguish two families of materials: glass and plastic.

- Glass test tubes (often reusable): able to withstand thermal shocks.

- Sodo-calcic: it is composed of 72% silica, 13% soda, 5% lime. It is the most common glass material and is a must for laboratories. It is suitable for volumetric purposes. With a good chemical stability, this choice of material is an excellent quality/price ratio.

- Borosilicate: composed of 80% silica, 13% boric anhydride, 4% soda and 3% alumina. It is the type of glass with the highest chemical resistance (resistant to water, acids, saline solutions, organic substances and halogens)

- Plastic test tubes (often single use):

- Polypropylene (PP): a very common type, it is a material combining rigidity and flexibility, resistant to a wide temperature range from 40°C to +120°C

- Polyethylene (PET): colorless, it is a saturated polyester type material resistant to a temperature variation between -40°C and +70°C

- High density polyethylene (HDPE) : semi-crystalline plastic, therefore resistant to abrasion, wear and tear and to a temperature variation between -70°C and +90°C

- Polystyrene (PS): thermoplastic material and therefore hard and brittle; ideal for solid product analysis with a temperature range of -40° to +80°C

To learn more about technical resins, click here!

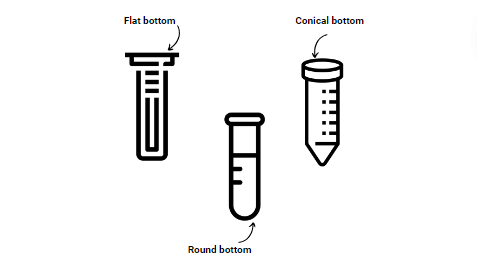

3 shapes, 3 uses to select the ideal test tube

The test tube is cylindrical, but the shape of its base varies. The three specific shapes recognized are: flat, round or conical.

- Flat-bottom test tubes: Flat-bottom test tubes are used for clinical, environmental, industrial or microbiological purposes.

- Round-bottom (U-shaped) tubes: Round-bottom tubes are ideal for laboratory, clinical, food processing and industrial applications.

- Conical bottom tubes (V-shaped): Conical bottom tubes are mainly used in centrifuges, both refrigerated and non-refrigerated. Due to their thin and smooth walls, they have high mechanical strength and good transparency.

3 types of caps for your test tubes

- Cap with fins : the fins allow to maintain the cap on the tube

- High form plug: perfectly seals the inside diameter of the tubes

- Capping cap: double internal collar for easy resealing

These different types of caps are offered in different colors: natural, white, pink, green, yellow, blue, gray, orange, red, purple, black … And in different sizes depending on the tube.

To determine your choice, determine the inside diameter of your tube.

Then check its compatibility with the tube material and check the compatibility with the centrifugation.

If you want to transport your tubes, choose winged caps to ensure a good hold of the container.

Don’t overlook these other criteria that make a difference when selecting the ideal test tube

Other parameters are important when selecting a test tube:

- Sterility: sterile, non-sterile or aseptic, this characteristic impacts the microbiological stability of the content

- Graduation: from 5ml to 5ml or from 2.50ml to 2.50ml or non graduated in the case where the sample analyzed or stored needs to be measured at a glance

- The presence of a rim or not: to facilitate the pouring

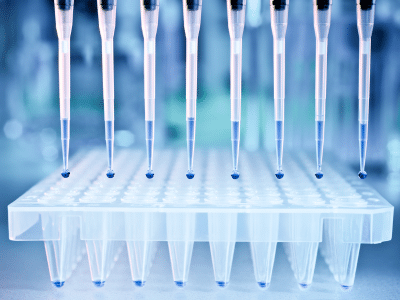

- The dimensions of the tube: in particular, if the use of a rack is necessary or if it must be inserted in an automat

- Volume: depending on the application

What to do when the supply of glass, the raw material for test tubes, is difficult?

In the current economic climate, we are facing a lot of upheaval, especially in the supply of glass tubes.

There are several plastic tube options that can replace glass tubes.

In medical microbiology, some polypropylene or polystyrene tubes can be adapted.

Polypropylene tubes are generally more resistant to impact and breakage than glass tubes, but they can be more difficult to clean and sterilize.

Polystyrene tubes, on the other hand, are generally easier to clean and sterilize, but they can be more fragile and less resistant to impact than polypropylene tubes.

It is important to choose a quality plastic culture tube that meets the needs of your laboratory and is suitable for the intended use. It is also important to follow good handling and sterilization practices for culture tubes to ensure the quality and integrity of test results.

Do not hesitate to contact us to advise you in your choice.