You use them every day in your anatomopathology processes, you know their smallest characteristics, their use has no secret for you: cassettes may still have some mysteries that we are delighted to unveil to you!

Everything you need to know about the industrial development of an anapath cassette

It is the research and development department of the manufacturer that designs the cassette, making sure that it meets the minimum requirements of opening safety and identification quality.

A mold intended to produce the cassettes by injecting a plastic material into them in plastic injection presses is then ordered. Careful tests are carried out on a first batch of prototype cassettes initially molded until it strictly meets the requirements identified at the beginning of the industrial project. When the prototype is ready, a first production test is launched, during 24 hours, without stopping. The manufacturer validates that the cassettes produced are within the dimensional and printing quality tolerances specified in the specifications. Finally, a few cases of each of the eleven proposed colors are produced for stock. These are the golden samples, the reference samples.

Everything you need to know about the plastic raw material used to manufacture an anatomopathology cassette

For histological cassettes, acetal (or POM for PolyOxyMethylene) is used.

It is a very resistant resin from a mechanical point of view and has the necessary flexibility for safe closing. It is also dense enough not to float and therefore will allow the resulting cassette to remain at the bottom of the reagent tanks.

All about the time it takes to produce a million cassettes

Cassettes seem to be a common laboratory consumable. However, each cassette has its own production cycle time, each production mold in which cassettes are injected and produced is different and has a different number of “cavities” (places in which cassettes are molded.

The most recent molds of LABELIANS’ partner, for example, have 8 cavities, and it takes between 10 and 15 seconds for an injection molding. It will therefore take 15 to 20 days to produce one million cassettes!

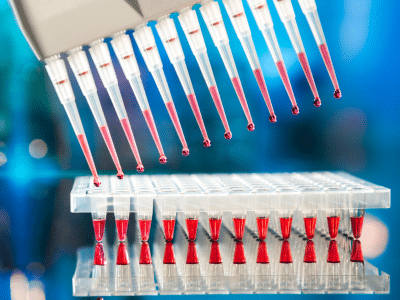

Everything you need to know about the quality control of cassettes for the anatomopathological process

For each production run, the dimensional, closure quality, as well as the printing quality on each of the printers on which the cassettes are to be used are tested.

All about how new models of cassettes for pathology are designed and produced

LABELIANS’ partner, Simport, relies heavily on the inventiveness of our founder. In Quebec, they have the reputation of being very creative, of being “patenteux” as our Quebec cousins say. Obviously, Mr. Lafond is inspired by a basic concept, but he is always looking for ways to improve the quality of the reagent flow, the ease of handling for operators, and the quality of the sample identification record, a parameter that is becoming increasingly critical with the explosion of traceability requirements mandated by regulatory authorities. Typically, from the time the idea was first conceived by their president to the time a new tape is released, it will have taken 18 to 24 months.

If you would like to know more, please touch base !