We have tried to answer most of the questions that arise when we present this method of characterising the temperature measurement of laboratory centrifuges in dynamic phase. Of course, we may not have answered yours. In this case, please do not hesitate to contact us.

The methods available for the measurement of this temperature parameter and for this laboratory centrifuge equipment are not well developed. Therefore, they do not allow us to know what really happens during a centrifugation cycle in the sample housing.

The service generally offered by metrological service providers is a heating measurement (difference in T°C after – T°C after centrifugation). This measurement is not very reproducible because the pre-conditioning conditions of all the accessories are not controlled.

Moreover, this method does not make it possible to detect a temperature increase during the centrifugation cycle. The second method generally used by internal metrology departments is to compare the indications of the control probe with a reference probe.

However, this method does not take into account the strong heterogeneity of the temperature in the chamber (the vessel) nor the impact of the rotation speed on the rotor assembly and therefore on the samples.

Therefore, the objective of the method developed by our laboratory is to allow the control of the centrifugation process from the preparation of the equipment to the end of the cycle for different speed-temperature couples. In this way, we will avoid any risk of alteration of the centrifuged samples and we will ensure the validity of the results.

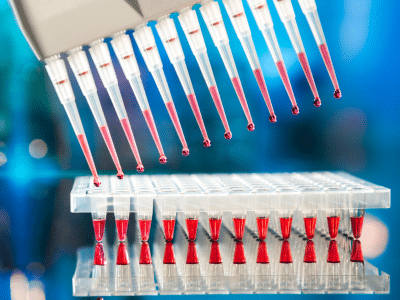

Temperature loggers are positioned at critical points in the system volume, at the sample locations.

They follow the temperature evolution during the whole centrifugation process, from the preparation to the end of the cycle. This allows the qualification of the pre-conditioning process of the equipment, called “transient regime”, to quantify the impact of the opening of the lid (loading simulation), as well as its capacity to generate the desired temperature conditions in stabilised regime called “established regime” and to rule on the conformity of the equipment.

The measurement of air temperature represents the worst case (amplitude of control oscillations). It has been demonstrated by the laboratory that the nature of the sample has no impact on the average temperature value once thermal balance is reached.

All laboratories centrifuging samples for which temperature is a critical parameter (BML, pharmacy, bio-techs, industry, cosmetics) wishing to know if their equipment has the capacity to meet the desired specifications.

This method is primarily intended for centrifuge manufacturers: prototype tests or tests on production lines. It allows developments to be made on materials (thermal performance), on compensation algorithms in order to limit the impact of speed, on hot-cold regulation, among other things, in order to simplify and shorten the pre-conditioning phase and make the centrifugation process reproducible. It opens a phase of progressive improvement of the performance of the proposed equipment to allow control and confidence.

Laboratory centrifuges as defined in IEC 61010-2-020: 2016.

However, there is a restriction to low speed centrifuges (< 5 000 rpm) with free rotors. Installations for angular rotors can be considered on a case-by-case basis.

The temperature range covered by this method is 0 to 50°C.

The speed range covered by this method is 0 to 5000RPM.

Yes, a panel of customers of LABELIANS smart service metrology laboratory were consulted throughout the development of this method. They made this project possible. Our customers have made equipment available for testing. The customers for the calculations, the rules for the declaration of conformity, the content and the clarity of the reports.

We invite you to consult the following documents:

GEN-REF-10: Traceability of measurement results – COFRAC policy

- The use of an accredited service falls under channel 2.

- The use of an internally developed service falls within the scope of channel 3-internal.

- The use of a non-accredited service falls under channel 3-external.

GEN-GTA-01: Technical guide to accreditation: traceability of measurement results

- See “Case of a centrifuge / temperature” p18

SH-GTA-01: technical guide to accreditation in medical biology

- For specificities related to medical laboratories (ISO 15189), see Appendix G: “Case of centrifuges in a pre- and post-analytical site for the temperature variable”.

The periodicity is at the discretion of the laboratories:

- Are you aware of any ageing (drift) on this equipment?

- Is it possible to carry out surveillance checks?

- Does appropriate maintenance allow the equipment to maintain its performance?

We invite you to investigate the following avenues: the analogy with the metrological strategy adopted for thermostatic chambers is a relevant avenue.

Temperature characterisation requires an instrument set and a measurement time that cannot be compared with the methods currently available.

Most of our clients entrust different service providers with preventive maintenance, safety checks, and metrological checks of the speed, time and temperature of their equipment, usually on an annual basis. We need to think about optimising the various services over the life of the equipment, in order to adapt the frequency of each check to the knowledge of the ageing behaviour of the equipment and its drift. Connected sensors should therefore make it possible to anticipate the actions to be taken.

We suggest a setpoint adjustment (analogy with enclosure characterizations).

Most centrifuges regulate only by cold production (heat rise is produced by friction). Rotational speed and temperature are linked. This method opens up possibilities for technological developments that will improve the performance of the equipment (manufacturing materials, impact of speed, etc.) and reduce the duration of the tests.

We suggest characterising each speed-temperature pair.

The performance time for a set point of a steady state is +/- 2 hours. One hour must be added for a transient regime.

The LABELIANS R&D department has developed this method for characterising the temperature measurement of centrifuges dynamic phase. This is a world first and has been accredited by COFRAC, a guarantee of quality and excellence.