Managing patient analytical diagnosis path from blood sample collection is a matter of following a large number of normative guidelines (if you need to refresh your mind about those , please refere to this serie of 5 blog posts).

Temperature si one of the most critical parameter in thne overall diagnosis process, on which we suggest to focus herebelow.

Collection: how does the temperature affect it?

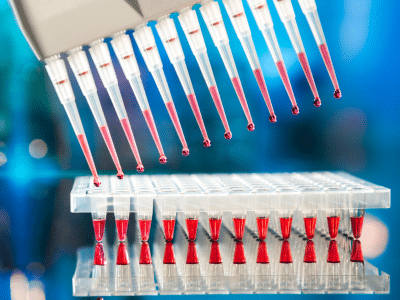

Once the sample is collected, the analysis type will define the storage temperature and timings.

It’s on those two drivers that you will base your temperature management strategy.

What about transport regulations ?

Biological samples transportation of biological samples requires a strict regulations compliance. The transport process is defined in section 5.4.5 of ISO 15189, Medical Laboratories – Quality and competence requirements:

« Sample transportation : The laboratory’s instructions for post-collection activities shall include sample packaging during transportation. The laboratory shall be able to produce a documented procedure for samples monitoring to ensure they are transported:

- within an appropriate timeframe considering the nature of the requested examinations and the laboratory discipline concerned ;

- within a temperature interval specified for sample collection and handling and with the designated preservatives to ensure the integrity of samples ;

- in a manner that ensures the integrity of the sample and the safety for the carrier, the general public and the receiving laboratory, in compliance with established requirements. »

Therefore, all packaging specifications described in the ADR (Agreement on Dangerous Goods) must be met by using a triple packaging made of a second inner packaging or a rigid outer packaging.

Know more about a client experience regarding ADR : https://laviedulabo.fr/en/transportation-bag-client-experience-advices-and-choice-criteria/

User safety and sample integrity must be ensured by the transport configuration.

Many recommandations are available for laboratories re analysis (temperature, stability timeframe, centrifugation) : source : GFHT in France, SIDIV (https://sidiv.fr/en/) HAS (https://www.has-sante.fr/jcms/pprd_2986129/en/home) …

For example, if we focus on cryoglobulin analysis and coagulation factors, the guidelines specify :

| Case | Cryoglobulin | Coagulation factors |

| Sample type | Blood | Blood |

| Transportation packaging | 1 : Blood tube 95kPa resistant 2 : Sealed transportation bag 3 : Cooler with eutectic system or transport box with electronic temperature control | 1 : Citrate Tube, 95kPa resistant 2 : Sealed transportation bag 3 : Cooler |

| Transportation temperature | 37 °C | 15-25 °C (Source REMIC) |

The WHO publication also provides information on transport conditions, as in the extract from WHO/DIL/LAB/99.1 Rev.2 below:

The use of temperature recorder requires to have a metrological monitoring.

LABELIANS smart service has the competence to do this metrological monitoring: calibration of the temperature chain :

| ITEM CODE | PRESTATION |

|---|---|

| CHAMPILEMAJLOG | Supply and replacement of used parts and batteries, software update |

| CHAQUACON | Total number of consignment points |

| CHAQUALOTS | Number of sensors batches to be calibrated |

| CHAQUASON | Total number of sensors to be calibrated |

| CHATABCON | Compliance table of calibrated temperature chains |

Reception at the technical platform, analysis : how keep correct temperatures in the instruments ?

Empty or full, all containers (tubes, bottles…) must be stored in rooms where the ambient temperature is totally controlled.

The conditions defined for transport must also be applied up to the centrifugation process or the storage of the incubator.

Thus, it is necessary to ensure that the expected temperature is compliant in these instruments.

Solutions are available to characterize the temperature during the dynamic phase of centrifugation or in the chambers.

To have the guarantee of temperature good control in the different instruments interfering with the process, you can trust the expertise of LABELIANS smart service.

LABELIANS smart service is the only one to have the competence to do this metrological monitoring: calibration of the temperature chain (temperature chain) and method for dynamic temperature characterisation of a crown.

| ITEM CODE | PRESTATION |

|---|---|

| CARCENETATRA1C | Dynamic characterisation of a centrifuge for a temperature set point in transient and steady state |

| CARCENETA1C | Dynamic characterisation of a centrifuge for a temperature set point in steady state |

| CARCENTRA1C | Dynamic characterization of a centrifuge for a temperature set point in transient regime |

Have you ever wondered why the temperature set point of a centrifuge was +4°C – +/- 2°C while for a refrigerated cabinet, this temperature was +5°C – +/- 3°C?

We reply: “the known heating of the samples during the loading phases of the centrifuge had led laboratories to reduce the set temperature and EMT from the specifications.”

And today, this practice continues.

Please note that manufacturers of automated systems are responsible for the temperature once the sample is handled by their automated system.

During analytical process, water bath can be used and this requires sensors control during the use but also cartography realization.

Analytical process is complete: store samples in a negative or positive freezer for archival purposes

The type of analysis and the storage time define the archival mode: negative or positive freezer.

To successfully manage this step, laboratories must ensure that the storage temperature is stable and meets the defined specifications.

LABELIANS smart service has the competence to do this metrological monitoring: calibration of the temperature chain (temperature chain) : characterization of thermostatic chambers under COFRAC accreditation.

| ITEM CODE | PRESTATION |

|---|---|

| CARTOENCE15C | Characterization of a cold room or a volume >2m3 for a temperature set point in established regime |

| COMCARTEMETA1C | Characterization of a combined freezer-refrigerator for a temperature set point in steady state |

| CARTOCOFRAC-80 | Characterization of a -80°C freezer for a temperature set point in steady state |

| CARTOENCE9C | Characterization of an enclosure <2m3 for a temperature set point in steady state |

Temperature management is essential for quality, precision or accuracy of analytical results at all steps of the pre-analytical and analytical process.

Throughout each process, we are there to support you in monitoring and ensuring patient safety.